How Labs Conducts Keyboard Testing

How Labs Conducts Keyboard Testing

### Behind the Clicks: The Rigorous Process of Keyboard Lab Testing

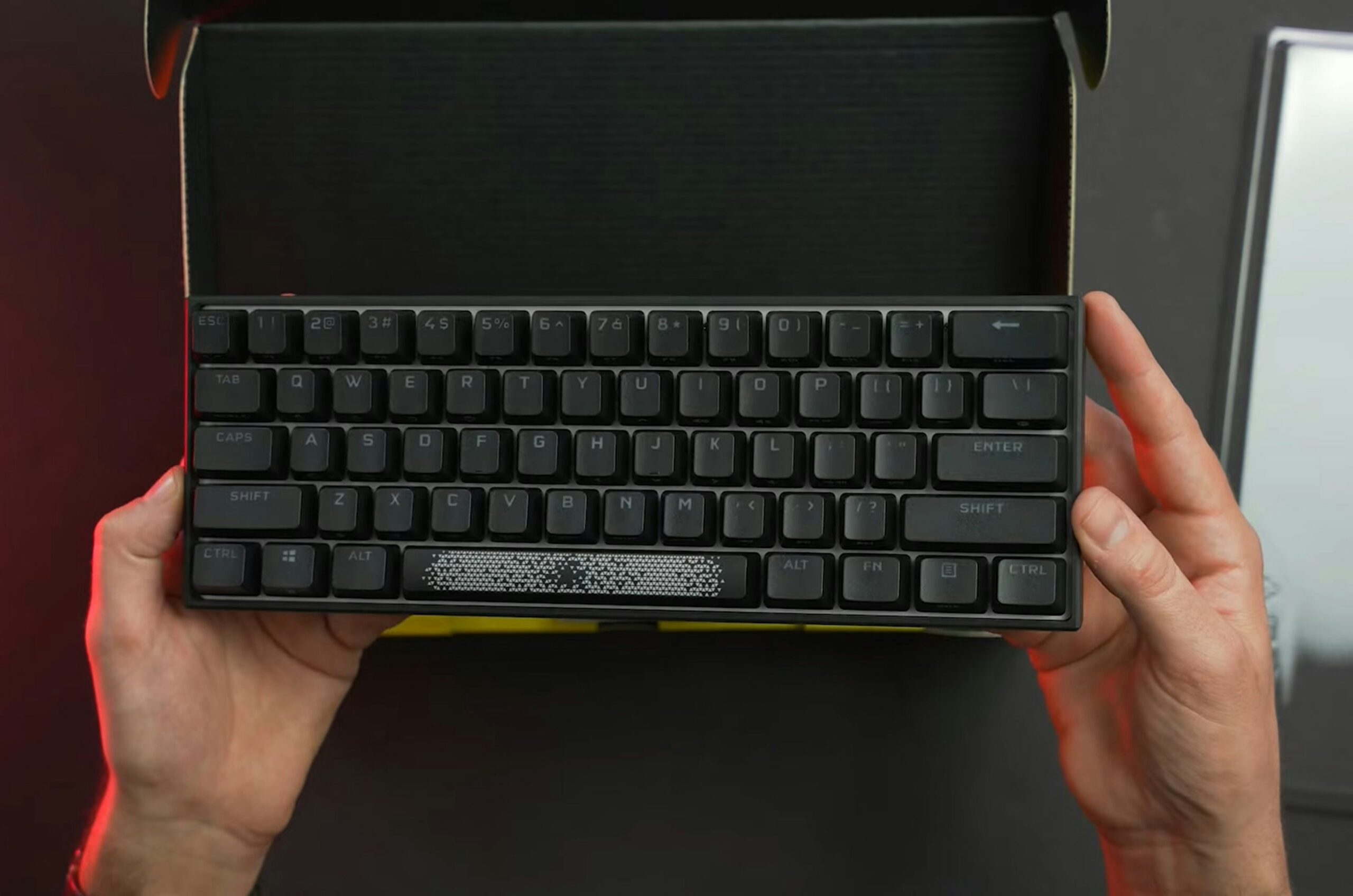

To the average user, a keyboard is a simple input device. You press a key, and a letter appears on the screen. But for the engineers and testers in a product lab, a keyboard is a complex piece of electromechanical hardware that must undergo a battery of intense tests to ensure it meets standards for durability, performance, and user experience. The journey from a prototype to a retail-ready product is paved with robotic arms, high-speed cameras, and meticulous human feedback. Here’s a look at how labs conduct keyboard testing.

#### 1. Mechanical Durability and Actuation Testing

The most fundamental question for any keyboard is: how long will it last? To answer this, labs don’t rely on human typists. Instead, they use custom-built machines with robotic actuators, often called “robotic fingers.”

* **Keystroke Lifespan Test:** A single key switch (like a Cherry MX Red or a custom membrane dome) is placed in a rig. The robotic finger then proceeds to press it, over and over, at a high speed. Switches are rated for a certain number of keystrokes—typically 50 to 100 million for mechanical switches. The machine will press the key until it fails, measuring whether the switch still actuates correctly and if the force required has changed significantly.

* **Force Curve Analysis:** Specialized equipment measures the precise amount of force required to press a key through its entire travel. This generates a “force curve” graph. Testers analyze this to ensure the actuation force (the point where the keypress registers) is consistent with the manufacturer’s specifications. They also check for smoothness, unwanted scratchiness, and the tactile bump (for tactile switches). This test is often repeated after millions of simulated keystrokes to check for wear and tear.

#### 2. Performance and Latency Analysis

For gamers and fast typists, milliseconds matter. Latency—the delay between pressing a key and the computer recognizing that input—is a critical performance metric.

* **Input Lag Testing:** Measuring latency requires precision instruments. A common method involves using an oscilloscope and a high-speed camera. The setup measures the exact moment the electrical contacts in the switch close and compares it to the moment the USB signal is sent to the computer. The time difference is the input latency. Top-tier gaming keyboards aim for a latency of 1ms or less.

* **N-Key Rollover (NKRO) and Anti-Ghosting:** Ghosting is when a keypress is registered that the user didn’t actually make, often when multiple keys are pressed simultaneously. Anti-ghosting is the feature that prevents this. N-Key Rollover means that each key is scanned independently, allowing you to press as many keys as you want at once with all of them registering correctly. Labs test this using specialized software that displays all currently pressed keys. Testers will systematically press dozens of key combinations, including common gaming clusters (like WASD + Shift + Space), to ensure the keyboard performs as advertised.

#### 3. Build Quality and Material Science

A keyboard must withstand not only typing but also the occasional bump, flex, and spill.

* **Torsion and Flex Test:** The keyboard is secured, and a measured amount of force is applied to twist or bend the chassis. Testers measure the degree of flex to determine the rigidity of the frame. A high-quality keyboard, often with a metal top plate or a solid aluminum case, will exhibit minimal flex.

* **Environmental and Spill Testing:** Keyboards may be subjected to varying temperatures and humidity levels to see if the materials warp or the electronics fail. For keyboards advertised as “spill-resistant,” labs conduct controlled spills. A standardized amount of liquid (usually water or a coffee-like substitute) is poured onto the keyboard, which is then left to dry for a specified period before being tested for full functionality.

* **Keycap and Legend Durability:** The letters on your keys shouldn’t wear off. Labs test this with abrasion machines that rub the keycaps with a textured material (simulating finger wear) for thousands of cycles. For different keycap types (like ABS vs. PBT plastic and doubleshot vs. pad-printed legends), these tests reveal which will stand the test of time.

#### 4. Ergonomics and Subjective Feel

Not everything can be measured by a machine. The subjective feel, or user experience, is just as important.

* **Human Panel Testing:** Labs employ a panel of testers with different hand sizes and typing styles (touch typist, hunt-and-peck, gamer). These testers use the keyboard for extended periods to perform standardized tasks, such as typing a specific document or playing a game. Afterward, they fill out detailed surveys rating the keyboard on comfort, key stability (wobble), stabilizer performance (on larger keys like the spacebar), and overall typing satisfaction.

* **Acoustic Analysis:** The sound of a keyboard is a major factor for enthusiasts. In a sound-dampened room, high-fidelity microphones record the sound of typing. This audio is then analyzed to create a sound profile. Engineers can see the frequency and volume of the “thock” or “clack” of the keys, identifying unwanted pings or rattles from the case or springs.

#### 5. Software and Feature Set Evaluation

Modern keyboards are often accompanied by powerful software for controlling RGB lighting, macros, and key remapping. This software is tested as rigorously as the hardware. Testers check for bugs, ease of use, CPU resource consumption, and the reliability of features like profile saving and macro recording. They ensure the lighting effects are smooth and the custom settings are saved correctly to the keyboard’s onboard memory, if applicable.

By combining these objective, machine-driven tests with subjective, human-centric feedback, labs ensure that the final product is not only built to last but is also a genuine pleasure to use.